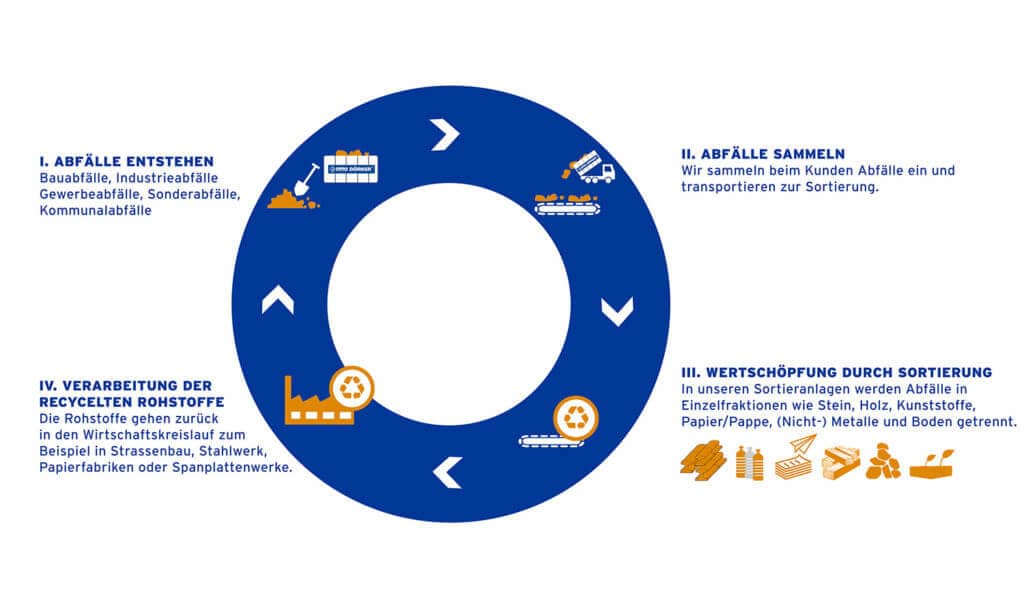

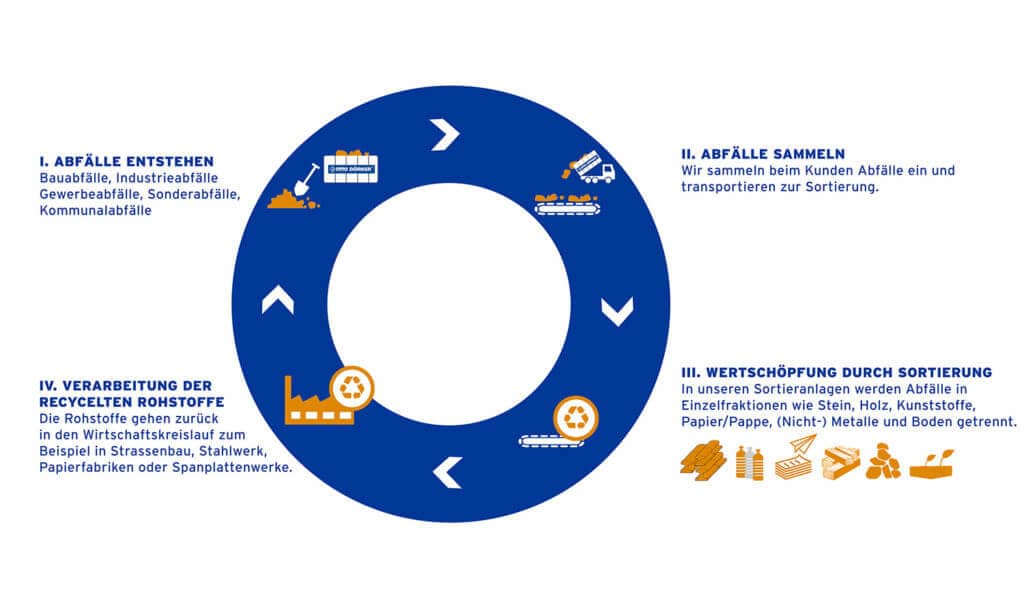

The contribution of recycling to the conservation of raw materials and energy is undisputed. Construction waste becomes a road support layer, waste wood goes into the production of chipboard, recycled paper becomes newsprint and packaging film can be reused as a rubbish bag. Collecting, sorting, processing and recycling, we deal with this every day. Recycling is our business and our value creation.

We do not do everything – but we are an important part of the recycling cycle. We collect many tons of waste and prepare them for the material recycling. The secondary raw materials thus obtained flow into the production of new products. Thus, our creation value contributes to the conservation of resources and the environment.

With more than 200 million t of annual waste, mineral construction and demolition waste, road breaking and soils are by far the largest waste streams in Germany. Through recycling of building materials, most of this waste stream is recycled for reuse, thereby protecting natural resources and landscape spaces.

In a multi-stage treatment process, we produce externally monitored and certified recycled construction materials from the mineral construction and demolition waste, which can be used in many areas as support and antifreeze layers, substrates as well as for track construction and road coverings. Untreated soil is treated and recycled in our various plants. We also accept mineral waste from the track construction and prepare them for recycling gravel or other recycling products. Careful control of the raw materials and state-of-the-art processing technology ensure consistent quality, both in ecological and technical terms.

Newspapers now consist of almost 100 percent recovered paper, as well as packaging paper and cardboard. Paper recycling requires 85% less water and two thirds less energy. The reuse of waste paper is therefore ecological and also makes economic sense. Although paper cannot be endlessly recycled, it does do so about 4-6 times.

With each pass in waste paper processing, the fibers become shorter, the strength drops, and thus fresh fiber material must be added to maintain the quality of recycled paper. As part of the recycling cycle, OTTO DÖRNER collects waste paper directly from customers and buys waste paper from other waste disposal companies. The waste paper is processed and marketed worldwide to paper mills for the production of recycled paper products.

What happens to the materials that cannot be recycled? The so-called Refuse-derived fuel (RDF) consists of non-recyclable plastics, paper waste, composite packaging or textiles.

Depending on the quality, the refuse-derived fuel is used as fuels in industrial, heating and cements power plant and replaces coal, heating oil or natural gas. To comply with the quality requirements, the refuse-derived fuel is analytically monitored. In addition to processing, OTTO DÖRNER also handles the transport of the refuse-derived fuel to the power plant, thus ensuring the continuous supply of the power plant.